Full-speed palletisation and on the road

Company

Südzucker

Contact

Markus Obermaier

German company, Südzucker, sought new ways to improve the flexibility in the automated palleting process. New Palcut sheet dispensing has provided a significant efficiency enhancement and a seamless switch from whole to half pallets.

As a major bonus, the company has improved the transport reliability as the pallets’ so-called slip angle is now over 27 degrees, which is highly significant in relation to the stringent German requirements on load safety on roads.

Issue: Palletisation

Interlayer sheets which were positioned incorrectly or fell down between the pallets and activated the photo cells can now be avoided at the Südzucker factory in Plattling in south-eastern Bayern. 300 pallets of sugar are palletised at the factory each day, which places great demands on an effective, non-stop palletisation process.

The problems occurred when the packaging robot lifted sheets from the interlayer sheet stack. The suction cups often picked up two or more sheets at a time. The sheets were then dropped on the floor or it resulted in inaccurate placing of the sheet/sheets on the pallet. This meant that the robot placed the next layer of sugar bags out of alignment, which led to a production stoppage.

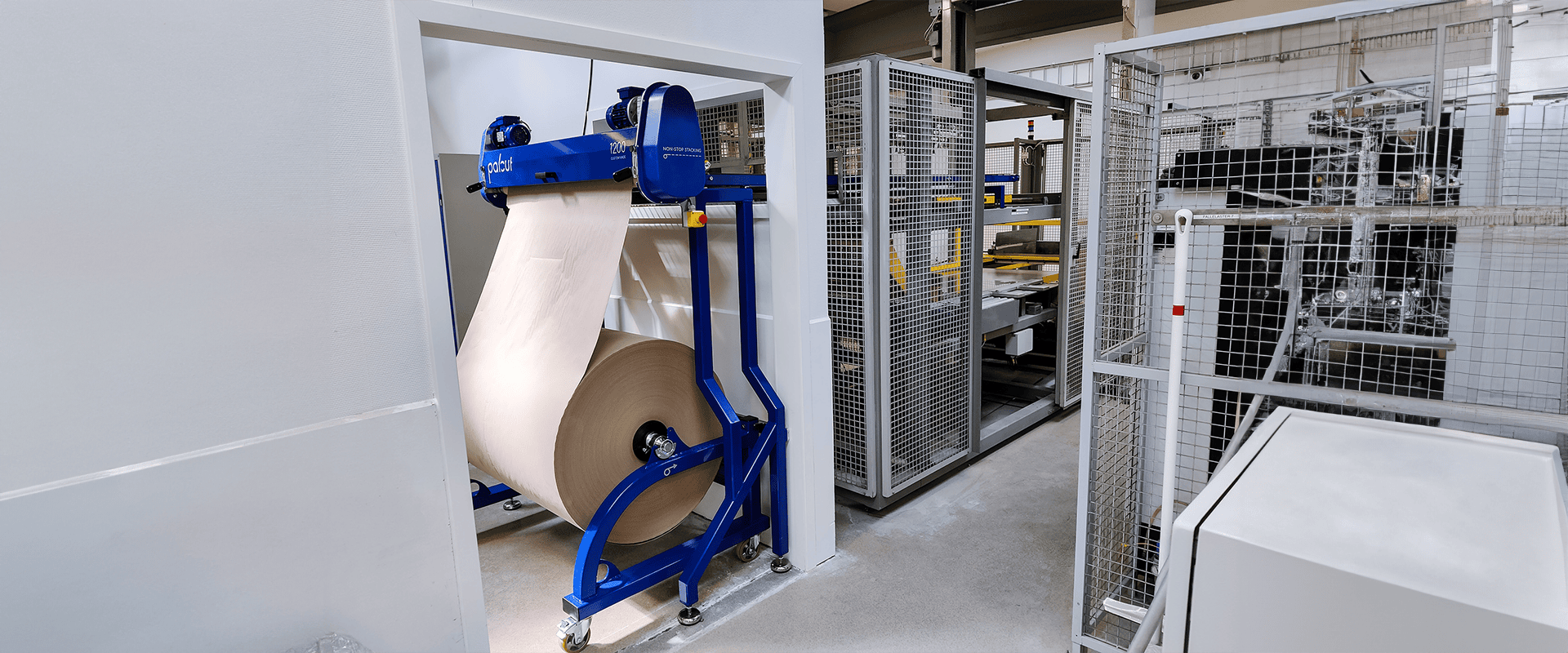

Zero stoppages

Three robot packaging lines are now equipped with Palcut 800/1200 automatic sheet dispensers. The interlayer sheet is cut and dispensed individually so that the robot can only lift one sheet at a time. In the three lines icing sugar is palleted in 250 g packs and 10 kg sacks and sugar in 1 kg bags. The Palcut machines are fully integrated into the packaging lines and switching between half and full size EU pallets takes place without interruptions.

“Since switching over to Palcut’s automatic dispensing of interlayer sheets, we have experienced far fewer problems in this area. This improves productivity and thus the efficiency of the factory. Since we have installed the Palcut solution, the handling of interlayer sheets is no longer an issue,” explains Thomas Mizerski, who is in charge of packaging and logistics at Südzucker in Plattling.

Close cooperation

The set-up was created in close cooperation with Piehler Industriebedarf, which is one of Palcut’s German dealers. Piehler has integrated the sheet dispensers into Südzucker’s existing palletisation system.

Stable transport

“Sugar is a difficult product to transport because it can easily shift about in transit – even though it is packaged in 1 kg bags and the pallet is secured with shrink wrap. By switching to the Antim65 anti-slip interlayer sheets from Palcut, the pallets have become more stable and safer during transport,” explains Markus Obermaier, who is in charge of further processing at Südzucker in Plattling.

Rudolf Sander from DEKRA Akademie Augsburg, which is an independent testing institute, elaborates: “We can confirm that the pallets now satisfy DIN EN 12195-1. This standard requires pallets to manage an angle of 27 degrees. We have created an angle test for pallets in which Antim65 interlayer sheets from Palcut are used and measured so that the pallets have a slip angle of more than 27 degrees. With the previous interlayer sheets, the pallets could only manage an angle of 18-22 degrees.”

Less storage

The Antim65 interlayer sheets used are of a 150 g paper quality, which is coated with an anti-slip coating. Both the paper and the coating are 100% recyclable. The interlayer paper is supplied in rolls up to 4,000 m long. This equates to several days’ use and unlike before, this means far fewer production stoppages when the paper feeder needs to be replaced.

Savings can also be made in terms of storage space, concludes Markus Obermaier: “We have been able to do away with a number of storage spaces.”

The Südzucker Group is Europe’s biggest sugar manufacturer with an annual production of 4.9 m tonnes.

The pallets satisfy DIN EN 12195-1. This standard requires the pallets to manage an angle of 27 degrees.

The packaging robot no longer loses interlayer sheets because only one sheet is cut at a time.