The Palcut Solution

For more than 20 years, we have helped industrial companies all over the world boost their efficiency, reduce their waste, and enhance their pallet stability – without them investing capital or making significant changes in their existing equipment. And we are here to do the same for you.

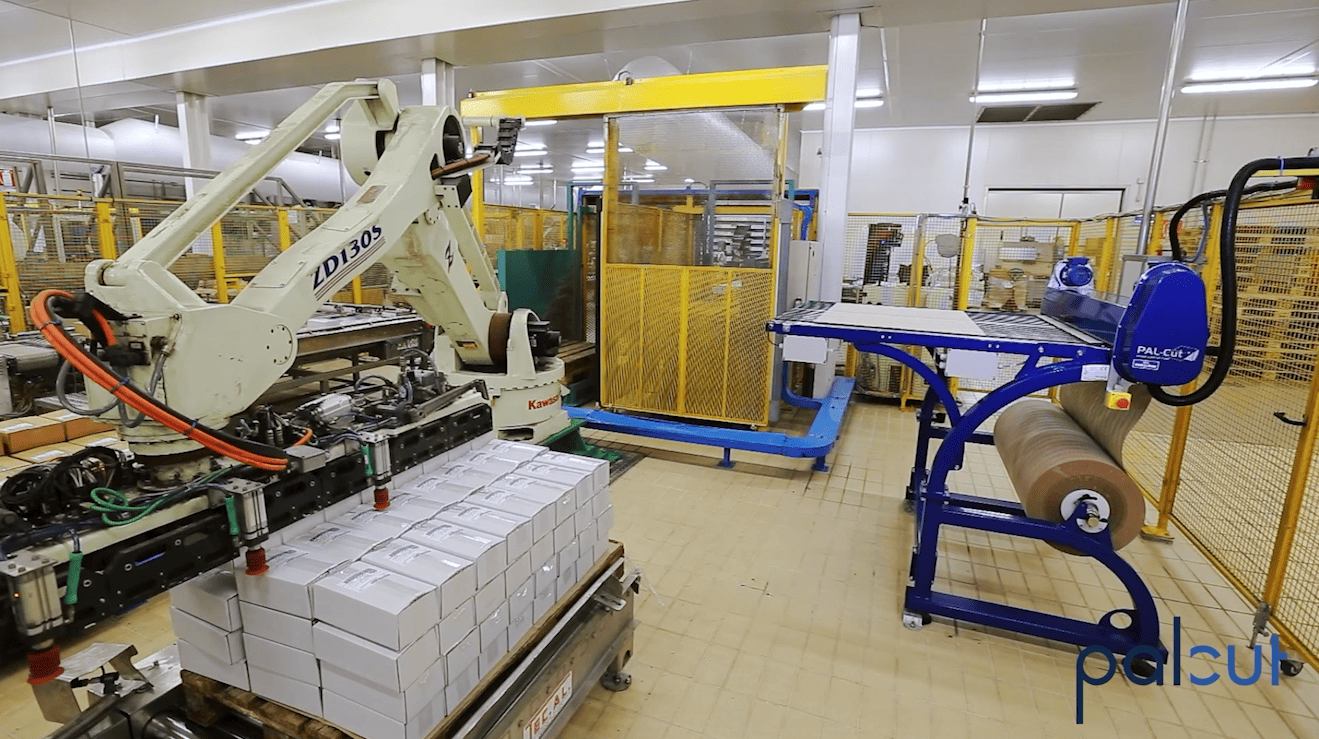

A Palcut Solution is when you combine one of our sheet dispensers / sheet cutting machine with reels of our anti-slip paper. This solution can be customised so that it fits 100% into your production, no matter what your situation and challenges may look like.

See how a Palcut Solution works

Why use a Palcut Solution in your company?

You free up storage space by up to 90% and reduce product damage during transportation.

You minimise your material consumption by up to 70% as well as your impact on the environment.

You simplify your work processes, increase productivity, and reduce downtime.

You save money from day 1 with plug and play installation.

Anything is possible – see some of our customised solutions

With a customised Palcut solution, we modify our machines, so you don’t have to make changes to yours. And anything is possible. Whether the sheet dispenser needs to deliver paper at a height of 5 metres or in a tight space, we will find the right solution for you.

Palcut Solution reduced 51 fully packed lorries to only 8

A customer used 1.2 million sheets of corrugated cardboard annually in their palletising plant. These were delivered with 700 sheets on each pallet with a weight of 0.276 kilos per sheet. So, every year approx. 1,700 pallets were delivered, corresponding to 51 full-load deliveries by lorry. By using a Palcut Solution and switching to half their current sheet weight, the customer has reduced their packaging consumption from 332 tonnes to 166 tonnes per year.

By replacing corrugated cardboard with anti-slip sheets from a reel, the number of delivered pallets has reduced from 1,700 to 240 – corresponding to 43 fewer full-load deliveries. According to the customer’s request to always have materials for 2 weeks in stock, the Palcut Solution has also resulted in the materials only taking up 11 pallets in the warehouse instead of the previous 76. This is because there are 7 times as many interlayer sheets on a reel compared to a pallet with corrugated paper. The achieved reduction in packaging is 166 tonnes of paper, which corresponds to 66 tonnes of CO2.

“Overall we are very satisfied with the new palletisation system, and the Palcut sheet dispenser has not caused a single stoppage.”

“The Palcut solution has seen productivity improve by 50,000-100,000 bottles a day, which is an improvement in percentage terms of 4-8%. Palcut is simply a brilliant idea.”

“The solution is simple and ingenious, because it cuts one sheet at a time from the roll, and when the packaging robot removes it, a new one is automatically produced.”

“This has solved the problems with pallets becoming unstable during transport. We haven’t had any customer complaints pertaining to pallet collapses since we commissioned the new systems in the summer.”

“Thanks to the Palcut solution we haven’t had any disruption to production, and we’re saving on storage space for sheets. We’re also spared the laborious manual reloading of sheets in the palletising line.”

“This improves productivity and thus the efficiency of the factory. Since we have installed the Palcut solution, the handling of interlayer sheets is no longer an issue.”

“With the investment in the two new, fully-automated packaging lines, we cut out much of the manual work, which has been important in reducing costs and increasing flexibility, while halving the consumption of paper during palletising, much to the benefit of the environment.”

“We are a make-to-order company in the private label market, where we have to be extremely flexible with delivery times, pallet sizes etc. With the new palletising line, we have become even better at meeting customers’ needs.”