Nørager Mejeri and Palcut protects the environment

Company

Nordex Food A/S Group

Contact

Torben Hovgaard & Karsten Nielsen

The dairy Nørager Mejeri is saving 100 tonnes of paper and protects the environment

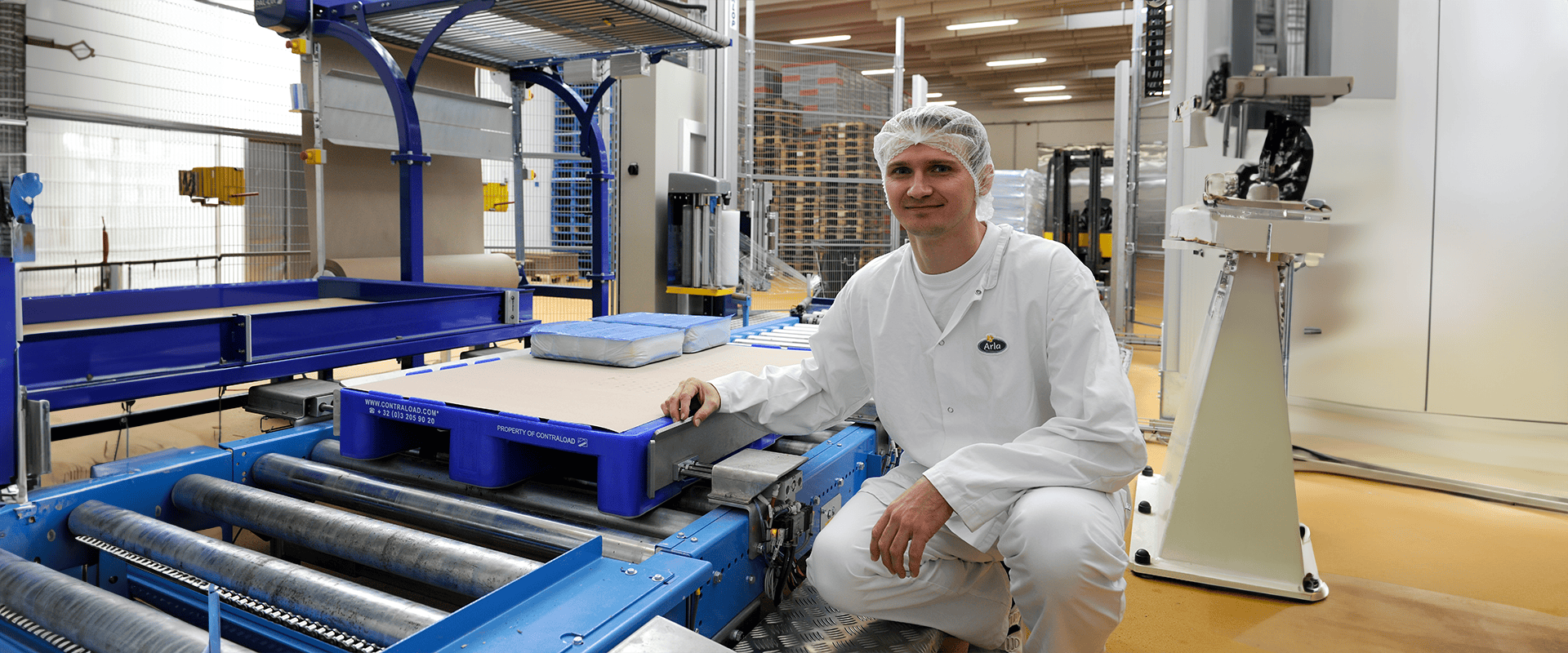

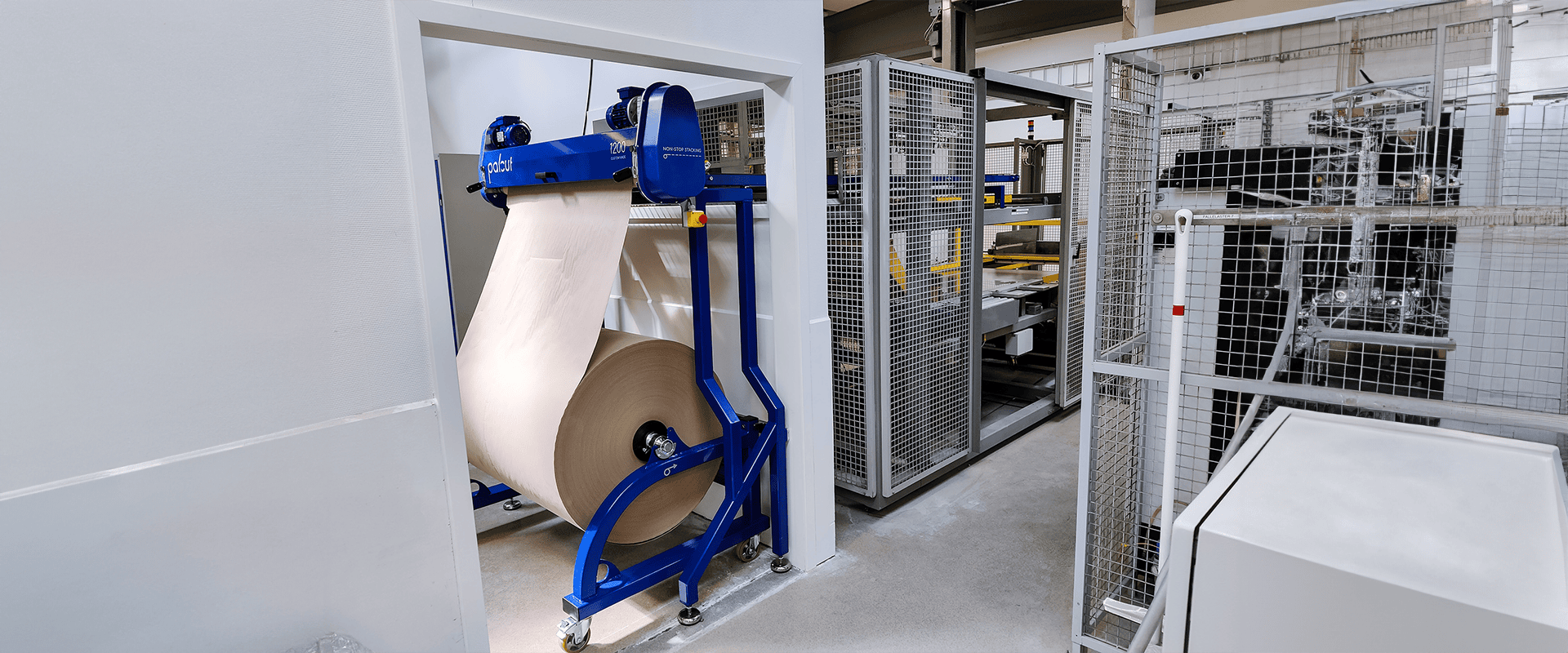

When the pallets with white cheese from Nørager Mejeri are transported, their old cardboard liners have now been replaced by Antim, which is a friction paper that reduces the risk of transport damage. Antim® is made from FSC® certified recycled paper and is automatically cut to the right size by a Palcut 1200. The machine is customised to the dairy’s new packaging and palletising lines.

Nørager Mejeri, northwest of Hobro, is part of Nordex Food A/S Group, a major producer of white cheese, typically known only from countries around the Mediterranean. The company is expanding and investing in new technology to streamline the production and packaging processes.

At the dairy, 19,000 tonnes of white cheese are produced every year, and up to 300 pallets leave the dairy every day with cheese in various packaging types and sizes. The many different cheese products are packed and palletised on two brand new, fully automated packaging lines. Here, production runs in two shifts from 4 a.m. to 10 p.m. There are also two older lines where palletising is still done manually.

Abandoning cardboard and streamlining the procedure

The two new packaging lines have recently been installed by Dansk Maskin Teknik A/S. The new facility automates the entire handling of the liners, and friction paper has been chosen instead of cardboard. This happened after mapping the entire procedure in palletising and the warehouse.

“Previously, we purchased cardboard as expensive single sheets and packed them by hand,” says Torben Hovgaard, Dairy Manager at Nørager Mejeri. “However, having manual processes in the production has simply become too expensive, and we want to avoid having to worry about overtime,” Torben Hovgaard continues.

The two packaging lines have each been fitted with one customised Palcut 1200, which automatically cuts and feeds the packing robot with Antim friction paper, cut from a 3,000-metre roll, which lasts for up to 14 days. Depending on the packaging and destination, Antim is used as a liner between every or every other layer.

Saves up to 100 tonnes of paper per year

The cheeses are packed in so-called Easy-Pack cups that are deep-drawn, and in a vac pack. They are packed on pallets up to 1.8 metres in height and cooled in a cold store before being wrapped in film.

The result of the new process is that Nørager Mejeri saves up to 100 tonnes of paper per year by replacing cardboard liners with friction paper in palletising. Antim is produced in a quality of 150 g, compared to 300 g for the old cardboard liner.

At the same time, the number of different liners to be kept in stock has been reduced to one with Antim, because Palcut 1200 automatically adjusts the size of the friction paper to suit the various pallet sizes.

Previously, they had many different cardboard qualities and sizes on the pallets. These would then be taken out, and employees manually placed cardboard between the individual layers of products.

“It was getting a little confusing with the many different formats of loose sheets in our warehouse,” says Karsten Nielsen, Chief Engineer at Nørager Mejeri and responsible for the installation of the new packaging lines. He continues: “Now, we only have one type of paper in the warehouse that comes on rolls, and together with Palcut A/S, we have simplified the many formats.”

FSC certified recycled paper

Antim is made exclusively from FSC® Recycled paper, which means that the friction paper is certified by the independent and international FSC organisation. With the certification, customers are guaranteed that only recycled paper is used and that this is verified by a third party.

“With the certified Antim, we support a sustainable paper cycle and minimise environmental impact, while meeting our customers’ high demands on transport reliability and efficient palletising,” says Keld Emil Jensen, Sales Manager at Palcut A/S.

The use of friction paper is growing

The use of friction paper is expected to grow by 60% in Europe from 2020 to 2025, according to a report from research firm QYResearch. The report identifies friction paper as the ideal solution to ensure the stability of goods on pallets during transport. “Demand is expected to rise, as this is a cost-effective solution that reduces the need for the use of tape and wrapping in film,” says Sales manager Keld Emil Jensen.

On the remaining two packaging lines, palletising is still done manually, but the plan is that these will be fully automated within a short time.

“With the investment in the two new, fully-automated packaging lines, we cut out much of the manual work, which has been important in reducing costs and increasing flexibility, while halving the consumption of paper during palletising, much to the benefit of the environment,” Dairy Manager Torben Hovgaard from Nørager Mejeri concludes.

Facts: Nørager Mejeri

Nørager Mejeri weighs in 1.6 million litres of milk per week, which is turned into 19,000 tonnes of white cheese every year. The dairy has 120 employees and is part of the Nordex Food A/S group with a turnover of DKK 1.8 billion. A significant investment in a new weighing system will enable Nordex Food to meet the demand for white cheese from the 70 countries that it is exported to. All cheeses from Nørager Mejeri are white cheeses of the Mediterranean type.